Understanding the Global Computer Chip Shortage: Causes and Impact

Written on

Chapter 1: The Importance of Silicon Chips

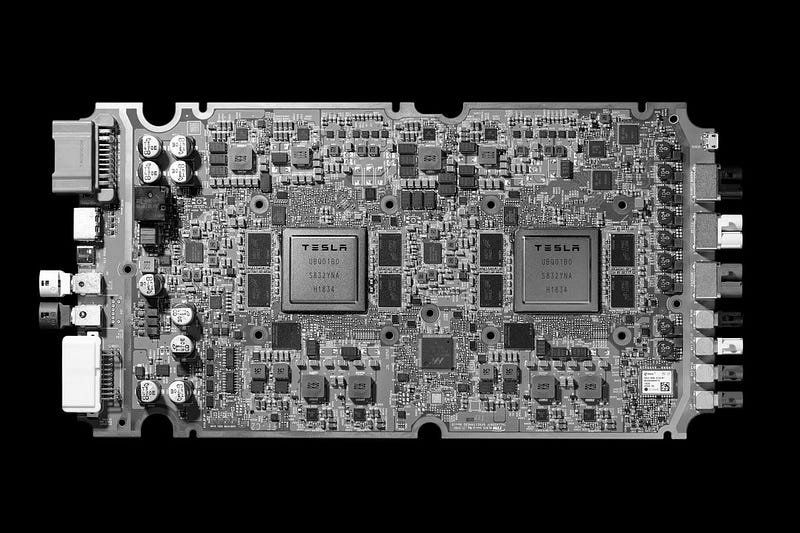

Silicon chips serve as the essential components of electronic devices. While they lack the biological properties of blood, they play a critical role in powering technology. Devices like smartphones, data centers, supercomputers, and military aircraft depend on these semiconductors to transmit crucial electrical signals. Within computing systems, they form the central processing unit, akin to a diligent brain. But what are the implications of a shortage of these vital chips, often described in dire terms as a famine, like the one we are currently experiencing?

Manufacturers such as Ford and Fiat have halted production lines. The much-coveted PS5 gaming consoles now face extended wait times due to restocking challenges. General Motors has paused operations in various locations across the United States, Canada, and Mexico. Mazda has also announced a reduction in production by thousands of units this year, while certain computers and components have become increasingly scarce. The automotive sector has been particularly hard hit, with estimated losses reaching $61 billion in 2021, as many firms were compelled to slow or cease the production of new vehicles. This disruption stems from the deep integration of semiconductor chips in automobiles, which power everything from Bluetooth connectivity and video displays to seat adjustments and even engine functionalities. Without new silicon chips, new cars cannot be manufactured.

Chapter 2: Causes of the Chip Shortage

The ongoing chip shortage primarily results from the disruptions caused by COVID-19, which impacted both supply and demand. However, even before the pandemic, many chip manufacturers struggled to keep up with the soaring demand for their products. As the pandemic set in, many chip production facilities shut down, and those that remained operational, such as Taiwan Semiconductor Manufacturing Company (TSMC), were unable to meet the rising demand. TSMC, which supplies Apple with its chips, dominates the global market, holding over 51% of the share.

The issue began to unfold early last year, when new quarantine measures led to the closure of dealerships and showrooms, while car manufacturing slowed significantly. The decrease in sales resulted in fewer chip orders from equipment manufacturers, triggering a chain reaction that caused further production dips in chip factories. It wasn’t until automotive plants reopened and consumers had more disposable income from stimulus payments that demand for cars surged again. Consequently, car manufacturers began competing fiercely for semiconductor chips, which were also in high demand for gaming consoles, televisions, smartphones, and other electronic devices that provided entertainment during the prolonged quarantine.

The first video titled "Why There's a Chip Shortage & The Use Case of Supercomputers" delves into the reasons behind the current chip shortage and discusses how it affects various industries, particularly the supercomputing sector.

Section 2.1: The Manufacturing Challenge

Why can't chip factories simply ramp up production to mitigate the shortage? The answer lies in the complex manufacturing processes involved in creating these chips.

The fabrication environments for these chips are pristine, often cleaner than surgical theaters. Creating a silicon chip entails a series of steps, including purifying, melting, and cooling silicon — the second most abundant element on Earth. Once cooled, this silicon is sliced into thin disks known as wafers, onto which chips are constructed. The completed product is compact yet three-dimensional, typically comprising numerous intricate layers of circuitry. Each chip undergoes rigorous testing to ensure it meets stringent specifications. The entire process can take anywhere from 6 to 26 weeks, meaning that it will take months before supply and demand can rebalance to alleviate the current shortage. Production levels may remain constrained until the fall of this year.

Chapter 3: Economic Repercussions and Future Outlook

Automotive industry representatives are urging the Biden administration to take action. They are advocating for Asian manufacturers to prioritize the production of semiconductor chips specifically for vehicles, rather than focusing on consumer electronics, which tend to be more profitable. Both parties are reluctant to accept blame for the ongoing shortage; chip manufacturers point out that automotive companies significantly cut their orders, while automakers contend that chip manufacturers are deliberately prioritizing consumer electronics.

Regardless of the source of the issue, the persistent shortage is adversely affecting the US economy. It will take approximately three months for chip production to ramp up significantly and start alleviating the scarcity. These silicon chips are expected to play a crucial role in technological advancements well into the 2040s, after which they may be succeeded by next-generation technologies.

The second video titled "Why is There a Global Chip Shortage?" explores the factors contributing to the global chip crisis and its widespread effects on various sectors.